Airbrushing 102: The Air Supply

By Chris Banyai-Riepl

Having talked about the brush part of the airbrush last week, now it's time to examine the air part. Just as there are many types of airbrushes out there, so it is with air supplies. We'll start out with a general overview of the requirements that an air supply needs to have and then follow that up with specific pros and cons to those different air supplies.

The Requirements

The needs of an airbrush's air supply can be narrowed down to quality and consistency. Good, clean air at a consistent pressure is all you need to produce good results with your airbrush. While it sounds simple, it actually can be quite challenging to achieve those results.

Starting with the clean part, this can be separated into two components: particulate and moisture. Particulate content in the air supply is only a problem with those air sources that draw in room air. For the most part, those types of air supplies have some sort of filter on the intake to minimize that problem. On the other side of the airbrush, spraying in a dusty environment can result in those particulates mixing with the atomized paint exiting the airbrush. This is a problem regardless of air source, and the only solution is a clean environment.

Moisture is a significant problem across the board, as it can wreak havoc with paint mixtures. Like particulates, this can be seen on both sides of the airbrush. While there is little one can do about spraying in a humid environment, a simple moisture trap between the air supply and airbrush will greatly improve the quality of the air. As its name implies, this device condenses the moisture out of the air, providing a consistent, dry air to the airbrush. An important point to remember about water traps is that they do need to be emptied, as once they fill up they will no longer remove moisture from the air supply.

Consistency is the second requirement of an air supply. For most air supplies this is controlled through a regulator. This allows the artist to maintain a specific air pressure, thus eliminating one of the variables in creating consistent results. While some air supplies can be used without a regulator, the advantages from using one makes it pretty much an essential part of an airbrushing system.

Types of Air Supplies

Now let's look at what's available to power up your airbrush. These can be separated into two categories: generated air and pre-packaged air. We'll start with the pre-packaged air first.

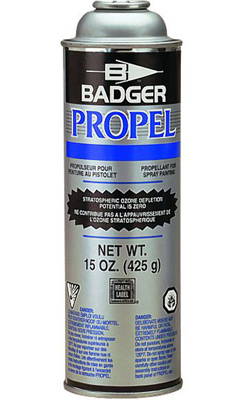

Canned Air

This is often the first air supply experience for the beginner airbrush artist. These resemble a can of spray paint, and they are not that dissimilar. The big advantage to these cans of air is their portability. They are small, which allows on to airbrush right on the workbench without having to set up a separate station.

This is often the first air supply experience for the beginner airbrush artist. These resemble a can of spray paint, and they are not that dissimilar. The big advantage to these cans of air is their portability. They are small, which allows on to airbrush right on the workbench without having to set up a separate station.

That one benefit, though, hardly outweighs the problems with canned air. These center around the second requirement listed: consistency. There is no regulator with canned air, and it is a finite air source. That means that as you continue airbrush, the air available slowly runs down. This creates a variable air pressure, which then requires a variable paint mixture to balance everything out. This puts canned air at the bottom of the list in potential air supplies.

Bottled Air

Bottled air differs from canned air in quantity (the bottles are much larger, and set to a higher pressure) and reusability (they can be refilled). Because of the higher pressure and larger capacity, bottled air can provide a consistent output through a regulator. This eliminates the major problem with canned air, and makes this option a very strong choice for airbrushing. As there are no moving parts, it is also the most silent choice.

Bottled air differs from canned air in quantity (the bottles are much larger, and set to a higher pressure) and reusability (they can be refilled). Because of the higher pressure and larger capacity, bottled air can provide a consistent output through a regulator. This eliminates the major problem with canned air, and makes this option a very strong choice for airbrushing. As there are no moving parts, it is also the most silent choice.

While one could conceivably get just about any gas compressed in a bottle, the only real choice is carbon dioxide (CO2). This is an inert gas that poses little danger and is a very common gas to find. The latter is an important factor, as the tank will need to be recharged every now and then. A good-sized tank, though, will last a long time, limiting the repeating cost. By the time one figures in the initial purchase price, the regulator, and the water trap, plus the occasional refill cost, bottled air becomes a very affordable method of providing an air supply.

Compressors

The most common form of air supply for airbrush artists is the compressor. These are often produced by airbush manufacturers, but are also available from industrial manufacturers. Compressors work in two ways. They can either provide air directly, or they can fill a tank that is then used for the air supply.

Direct air compressors are generally less expensive than their tanked counterparts. However, if you choose this route, you will want to get one specifically engineered for airbrushing. The reason is that most of these are diaphram-based compressors, which create a pulsation in the output line. This pulsation translates up through the airbrush and creates a pulsing paint output. Compressors specifically designed for airbrushing can be designed to minimize this (although it can never be eliminated). Adding a pressure regulator further helps, as does a reservoir water trap. Finally, the other benefit to these airbrush-specific compressors is that they are generally quiet. labeled as 'silent', they do make noise, but that noise in usually lower than the sound of a regular household fan.

Compressors with tanks combine the benefits of bottled air with the advantages of a compressor. This is the most expensive option, at least initially, but it has the major benefit of only having an initial outlay, as a good compressor with tank will last the lifetime of the modeler, generally. Like the non-tanked compressors, these can be found in both hobby-specific types and industrial types.

Compressors with tanks combine the benefits of bottled air with the advantages of a compressor. This is the most expensive option, at least initially, but it has the major benefit of only having an initial outlay, as a good compressor with tank will last the lifetime of the modeler, generally. Like the non-tanked compressors, these can be found in both hobby-specific types and industrial types.

While industrial types might be cheaper, they are generally designed for commercial operations where noise is not a concern. While this might not seem like a problem, believe me, one evening of airbrushing quietly suddenly interrupted by a 100+ decibel compressor kicking in will result in some pretty twitchy paint finishes. This can be minimized by increasing the tank size, but that has other issues, most notably, compressor footprint. As such, this becomes the largest option for an airbrush air supply.

Conclusion

There are many options for air supplies, which is great for modelers. Aside from the canned air option, any one of these will be a good choice for the modeler, and it will all come down to personal preference and availability. Next week we will examine the final item in airbrushing tools, the paint.