Most of us know the history of the Fokker Eindecker and how Anthony Fokker synchronized a machine gun to fire through the prop of his monoplane in 1915. Rather than repeat the history here I will refer you to the books in the references below for a complete history of the Eindecker. This article will concentrate on building the Eduard kit and correcting some of the problems in the basic kit to make a more accurate model.

The Kit

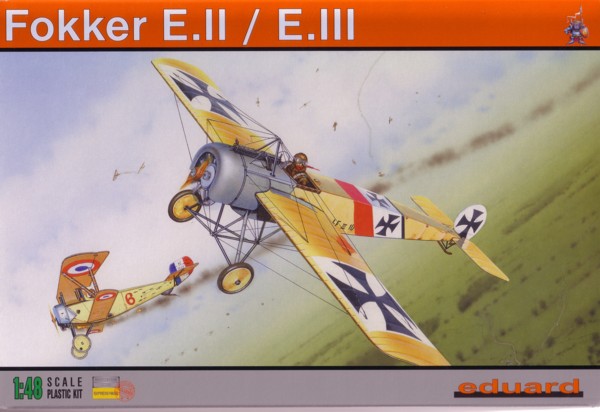

Eduard’s #8156 Fokker E.II/E.III comes nicely packed in the usual Eduard box. The first release in 2008 was a full kit that they used to call Profipack, and contained the plastic sprues and two photoetched frets, one pre-painted for gauges and various details (including a full color map) and a larger one in a silver nickel plated metal. They also included a painting mask for the windshield. My kit was missing the windshield but that was easy to make from clear plastic. It has markings for 5 different aircraft, including Ernst Udet’s E.II, although the red band may not be an accurate color. Also my red band had a small #19 printed in black right in the center of the band, somehow Eduard printed the decal # on the decal? Also the wing white cross fields are too big, they should be square not full chord. There are three sprues of tan plastic with several optional parts such as wings, props and cowls. There are also an extra wing and 7 cylinder engine for the E.I that are marked not to be used. Upon first look there was a lot of fine detail, but a few things did not look correct when compared to photos in my references. I was able to obtain the decals from Eduard’s Dual combo kit # 1141 Die Erste Kannonen limited edition. This kit had markings for the E.II 37/15 flown by both Oswald Boelcke and max Immlemann, both obtained at least one kill while flying this aircraft. Due to the significance of Germany’s best early aces flying this aircraft I decided that I would build this one even though it had no elaborate personal markings.Research and references: My main references were as follows:

- Fokker E.I/II Windsock Datafile 91 by P M Grosz 2002

- Early German Aces of World War 1 Osprey Aircraft of the Aces 73 by Greg Van Wyngarden 2006

- Fokker Eindecker in action Squadron/Signal 158 by d. Edgar Brannon 1996

Looking at photos in these references the fuselage of the Eindecker should be very smooth, but the kit one has what appear to be rib tapes molded over the fuselage framework. This combined with the instructions saying to paint the seat RLM 02 gray lead me to post a question on the Aerodrome forum. This lead me to another great reference source, Josef Scott has been researching the Fokker E.I/II and had already made a list of problems with the kit. He also sent me some unpublished drawings that he had done which he plans on using for a future issue of Windsock, and they include features that were missed in Windsock 91. Here are the problems as noted by Josef Scott:

- To make an accurate E.II the ammunition storage and feed are incorrect as provided.

- Sand off all internal structure contours on the outside of the fuselage fabric.

- There are no rib tapes on the rudder and elevators.

- The map case should be on the port side next to the seat.

- The cockpit floor should extend all the way to the bulkhead behind the seat, and the bulkhead itself is also plywood.

- The shoulder harness does not have the connecting chest piece.

- The rear fuel filler should be off-center to starboard.

- The cockpit coaming should extend all the way forward under the metal side panels.

- The fabric lacing on the underside of the fuselage is not correct; it should only go back as far as the tail skid.

- The fairings attached to the undercarriage struts only go behind the struts.

- The various doors and openings in the nose panels are not correct, the side doors were not hinged but slid up and down inside the fuselage. Also there should be a large open aperture in the lower panel to allow downward viewing. The lower end of the joystick protrudes through this as well.

- There is also a wind deflection panel riveted to the chin between the undercarriage struts.

Now I was ready to paint the metal parts, forward fuselage and cowl, and also the wing walks were sprayed with the Floquil Old silver and hand brushed for the squiggle pattern. Once it dried I mixed a 50/50 mixture of Old Silver and Testors clear glosscoat with a little lacquer thinner and lightly oversprayed the panels. This toned down the squiggles and made them look more realistic.

Then I masked off all of the metal panels. I sprayed all fabric parts with Model Master Radome Tan, including the wings and elevator. I had already sanded off the thick ribs on the elevator since there should be no rib tapes here, only the outline of the actual rib would be seen. The Radome Tan makes a great primer for the acrylic topcoat and allows me to do my rib work next.For the fuselage framework and the ribs on the elevator and rudder, I used a brown Prismacolor pencil to draw them in at the correct location. Then I sprayed a light coat of Misterkit German clear doped Linen mixed with a little future to give it some strength and I used some Liquitex flow Aid which keeps the acrylic from plugging up the airbrush. The rudder was painted white allowing the ribs underneath to show through – just barely.

For the wings I used a slightly different method, since the actual wings had wooden or cane strips tacked over the ribs to keep the fabric tight, I kept the Radome Tan for the rib color. I masked them off with Chartpack drafting tape of the correct thickness. Once dry I oversprayed the ribs with a dark earth color, just a thin line airbrushed right over the tape. This looks like a shadow once it is oversprayed and the tape is removed. I then sprayed a few light coats of the German clear doped linen, and once it dried removed the rib tape masking and overcoated the fabric areas with Future to prepare it for decals.

I started with the white cross fields on the upper wings. I used Micro set and Micro sol, but was unable to get rid of bubbles along the ribs, even with multiple coats of Micro sol. After a couple of days I tried some champ Decal setting solution and that seemed to do the trick and pull the decal down along the ribs.I applied all of the fuselage markings at this time. As with most World War 1 models, you must completely paint and overcoat the fuselage, wings and elevator & rudder before assembling them and rigging them. After all decals were dry I wiped them off with water to clean any excess setting solution or glue that will turn yellow or brown years later (don’t ask me how I know this). I then gave all the fabric areas a coat of Testors semi-gloss lacquer, this gives the plane the correct sheen of a doped aircraft, since both a dead flat coat or a high gloss coat both look wrong for the early clear doped linen aircraft.

Now the tape was removed from the metal panels and it was time to begin assembling the main parts. I began with the elevator on the tail, but could not get it to adhere properly, since you must glue a round rod to a flat edge on the rear of the fuselage. I found a good way to do this was to drill holes where the hinges were located and insert short pieces of .020 brass rod. Then I drilled two holes in the rear edge of the fuselage for these rods to

Now it was time to plan the wing attachment and rigging. The main rigging are the control wires that were used to warp the wings and do the job of ailerons. The key point of the rigging was part C53, this plastic strut must support all of the rigging and also the control wire pulley which is photoetched part PE37. I started by drilling two holes in the bottom of C53 and adding brass wire pins, and drilled holes in the upper deck where the dimples were molded for these. This will give it more support to hold up the control wires. I also drilled a hole through the front top of C53 and a hole in the back where the pulley would attach. I made turnbuckles from thin wire twisted around a drill and put one turnbuckle on each side to attach the front wires to. I next drilled 4 holes in each wing where the control wire attachments were molded. I drilled all the way through the wing since I wanted this rigging to be structural and keep the wings straight. Next I test fit the wings, the holes in the fuselage needed a little cleaning out to fit the wings correctly. I made a jig from Legos to hold up the trailing edge of the wing evenly, and glued both wings on with Testors liquid cement and a fine brush. You can see this jig in my photos, unfortunately it is out of focus but it gives a good idea how to align the wings correctly.

Then set it aside overnight to dry completely before rigging begins. While this was drying I got some silver monofilament thread that is used by fly fishermen to make flies, that would be my main rigging material for the wings. I cut two pieces about 2 feet long and stretched them slightly to take out the slack. I found the center, and folded the photoetched pulley and attached it to the center of the two threads with acc. I attached clothes pins to the pulley and both ends of the thread and let it sit hanging from my peg board overnight to take all of the slack out of the rigging material.Next I used a small piece of brass rod to attach the pulley to the hole I drilled in the control wire strut part C53. I also tied two pieces of the thread to each of the forward turnbuckles. Then it is a simple matter to thread the wires through the holes in the wing, stretch them tight and glue the ends to the center of the landing gear strut with a drop of acc. When dry put a drop of acc in the hole going through the wing, these wires also provide structural support. The wires from the pulley are done the same way but be careful when pulling them through the holes in the wing, you do not want to pull the pulley off of the strut with too much pressure on the strings. The ends of these wires go to the photoetched control fittings attached to the rear of the landing gear. Once they are dry trim the ends with sharp fine pointed scissors since it is hard to get a knife blade in there. There are a couple of short reinforcing wires on the forward fuselage that were added from ceramic wire. When dry I added the photoetched turnbuckles included in the kit, they are simply glued right over the wires with a drop of white glue and look pretty good for flat pieces.

Finishing touches include adding the machine gun, which uses all of the kit parts except the barrel made from a thin hypodermic needle, and the sight, a photo of this aircraft shows that it had a round sight and not the early rectangle shaped sight in the kit. I found an extra one on a Albatros photoetch sheet. For my guns I paint them overall Gunship Gray, and give them a heavy wash of flat black. When dry I grind up some graphite from pencil lead and rub this into the finish with an old brush to give it a metallic sheen. I glued the gun in position and added a blast shield to the forward cowling made from a piece of matte Bare Metal foil. This has an adhesive back, and you just cut it to size and put it in place. The final detail was the prop, Part A9 looked like the best match to photos of the actual plane. First I scraped off the hub detail. I painted it an acrylic light sand color, added laminations with a dark brown colored pencil, and gave it a heavy coat of Burnt Sienna artist oil paint. The photos of the early Fokker props all appear to be stained or painted a dark color, and this seems like the best way to finish them. Once it dried I gave it a couple of coats of Future for a gloss finish. Then I applied the decals and the photoetched hub. A wash of flat black picked out the bolt and hub detail. Then the prop was snapped into place.Last but not least, I gave the forward nose and underside of the fuselage several washes of artist oil paint, various shades of burnt umber and black were mixed and applied to represent the castor oil staining, especially along the lower longerons and the fuselage frame as these areas really appeared to suck up the oil in original photos. The stitches along the bottom also got a heavy wash of this simulated castor oil. The good thing about oils is if it looks like you put too much on you can go back later with a cotton swab dipped in thinner and wash some off.

So there you have it, the long way to build what appears to be an accurate Fokker E.II kit. I am glad to have added this to my collection, now I can only hope that Eduard will do an E.IV in this scale, and also that they will get away from the overly heavy rib tapes in areas that are not accurate, it looks like they have also done this on the recent Albatros D.III OEF kits. Well enough preaching, I would like to thank Eduard for providing us with a great starting point for this important aircraft and only hope that they keep up the production of these great world War I kits.

Thanks to Eduard for furnishing the review kit, and to Josef Scott for furnishing me with copies of his original drawings.