Tamiya 1/35 Panzer IV Ausf D

By Michael Benolkin

|

|

The Kit

The Kit With a few exceptions, I decided to build this kit straight from the box. The first step was to use a variety of Evergreen plastic and cyano filler to plug up the holes in the hull bottom. I didn't worry about what little detail existed on the underside and sanded the whole surface smooth. As you can see in the photo below, Evergreen plastic was used to fill in the gaps between the upper and lower hull, with a brace installed across the lower hull to eliminate any 'flex' in the lower hull that might break the bond between hull halves later on. Access to this area is virtually nil once the halves are joined and the track installed.

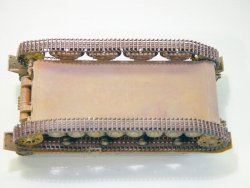

With a few exceptions, I decided to build this kit straight from the box. The first step was to use a variety of Evergreen plastic and cyano filler to plug up the holes in the hull bottom. I didn't worry about what little detail existed on the underside and sanded the whole surface smooth. As you can see in the photo below, Evergreen plastic was used to fill in the gaps between the upper and lower hull, with a brace installed across the lower hull to eliminate any 'flex' in the lower hull that might break the bond between hull halves later on. Access to this area is virtually nil once the halves are joined and the track installed. The turret was also assembled in the buttoned up mode and the only deviation from building straight out of the box was replacing the kit barrel with an aftermarket turned aluminum barrel (sorry, I don't recall the manufacturer).

The turret was also assembled in the buttoned up mode and the only deviation from building straight out of the box was replacing the kit barrel with an aftermarket turned aluminum barrel (sorry, I don't recall the manufacturer). I assembled the upper and lower hull according to the instructions and touched up the base color. The exhaust system and pioneering tools were also added to the hull at this time. The track was the next to be installed and we are ready to finish.

I assembled the upper and lower hull according to the instructions and touched up the base color. The exhaust system and pioneering tools were also added to the hull at this time. The track was the next to be installed and we are ready to finish. The model was airbrushed with a mixture of Future, Tamiya Flat Base and Desert Sand to provide a dead flat finish and to 'wear' the markings into the background color. I use the basic trio of Future (for the acrylic base), Tamiya Flat Base (a flattening agent designed to flatted Tamiya glass acrylics) and Isopropyl Alcohol (to thin the whole mixture to get through the airbrush. A 33%-33%-34% mixture will render a dead flat finish on the model. Of course a 50%-50% mix of Future and Alcohol will render a solid gloss. Therefore, you can experiment with the amount of Tamiya Flat Base to get varying levels of semi-gloss out of your finish.

The model was airbrushed with a mixture of Future, Tamiya Flat Base and Desert Sand to provide a dead flat finish and to 'wear' the markings into the background color. I use the basic trio of Future (for the acrylic base), Tamiya Flat Base (a flattening agent designed to flatted Tamiya glass acrylics) and Isopropyl Alcohol (to thin the whole mixture to get through the airbrush. A 33%-33%-34% mixture will render a dead flat finish on the model. Of course a 50%-50% mix of Future and Alcohol will render a solid gloss. Therefore, you can experiment with the amount of Tamiya Flat Base to get varying levels of semi-gloss out of your finish. Once this had dried, I drybrushed the entire model with medium gray to bring out the details. This was then subjected to the complete Rust-All four-part weathering process that really gives the tank the 'well used' look. Of course, special attention was given the exhaust system for corrosion.

Once this had dried, I drybrushed the entire model with medium gray to bring out the details. This was then subjected to the complete Rust-All four-part weathering process that really gives the tank the 'well used' look. Of course, special attention was given the exhaust system for corrosion. This was a fun project that was designed to test a few new (to me) weathering techniques for lighter color finishes. I am pleased with the effects and will be giving these another go on some more challenging projects in the near future.

This was a fun project that was designed to test a few new (to me) weathering techniques for lighter color finishes. I am pleased with the effects and will be giving these another go on some more challenging projects in the near future.