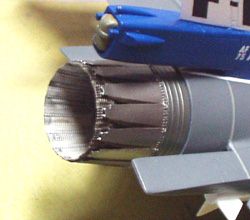

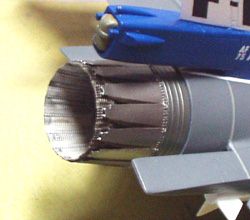

Building a 1/48 scale F-16XL |  | Introduction The F-16XL could be considered a sort of "ultimate" Viper, with the capability to carry twice the ordnance much farther than a standard F-16. These goals were met using as many components from regular F-16s as possible. The two prototype F-16XLs were built by converting two existing preproduction Full Scale Development F-16As. The original fuselages were stretched with two plugs, and the rear plug was made to angle the rear fuselage upward 3 degrees. A newly constructed crank delta wing of much larger area replaced the original wing and horizontal tailplanes. The second F-16XL also was converted from a single seater to a twin cockpit. The two XLs were extensively tested by the US Air Force and proved to be very capable strike a/c. Perhaps the only design goal not achieved was supercruise; it had been hoped that the aerodynamic changes would allow the XLs to fly supersonically without using the afterburner. The planes in fact demonstrated a very high transonic cruise but still required the reheat to go faster than sound. The F-l6XL was not put into production because the Air Force couldn't afford to buy both the F-16XL and the F-15E so Fort Worth continued to build standard F-16s and the F-15 production line, instead of closing down, began production of F-l5Es. Unlike most other prototypes that failed to reach production the XLs have avoided both the scrap yard and the museum. In recent years NASA has used both XLs for research. I've long wanted to build an F-16XL - it not only has striking good looks but is refreshingly different from the by now archetypically familiar standard Falcons. I've also long been a fan of the Convair (then General Dynamics, and now Boeing!) deltas, and the XL represents the modern incarnation of the delta wing fighter. Now I build mostly quarter scale, (please no scale wars!), and there's no kit of the XL in 48th. The options in other scales aren't too good either. The 1/72nd scale Monogram kit needs not only detailing but also surgery to make it right. Seems they put the fuselage plugs in the wrong places. Kangam, I believe makes a kit in 32nd scale and while I haven't seen it the word is that it accurately reproduces the errors of Monogram's. The best kit is the LS/ARII 1/144 model, which at least is shaped like an XL but that's too small for much 'presence' on the display shelf. The others are too inaccurate. Besides, I was itching for something to stretch my abilities so when Al Superczynski told me he had the Fall 1984 IPMS/USA Quarterly with a well done article by Keith Svendsen on how to correct the major problems of the Monogram 72nd scale kit the die was cast. Fortunately the article included 72nd scale three views, photos, detail drawings, and, most importantly, a scale drawing of where to add the fuselage plugs. I printed these at 150% to get 48th scale and went to work. The first thing I did was to splice two Hasegawa fuselages together to make a longer fuselage. General Dynamics made a five-piece fuselage; front, middle, and rear, with both front and rear plugs. That seemed like a lot work, each splice meaning more filler and room for error. I found that I could achieve the same stretch by cutting one Hasegawa fuselage to the length of the middle section with the plugs, only cutting off the nose and rear to length. The second fuselage contributed the forward and rear sections. This gave me a three-part fuselage, front to rear. I did the top fuselage first, being careful to match the contours of the plan. The forward plug would have gone through in the area canopy behind the pilot. To avoid having to rework the area where the canopy goes, I notched the middle section so that I could leave the front section longer in the area around the canopy. The bottom fuselage was stretched to match the top. Okay, I have a long fuselage, how do I make a wing? I can't recommend that you do it this way, (more of that later) but here's what I did. The most suitable material I could find was 0.10 plastic card. I glued copies of my plans to the plastic and made an outline. I cut this out and tapered the front face to a thin leading edge. I noticed that the regular F-l6 wings had the same angle between the leading and trailing edges as the outer panels of the XL. They just needed to be swept back and trimmed. The outer panels of the plastic card wings were cut off and the kit's outer panels added, using a pin for strength. The trailing edges were also recycled from the kit wings and spliced into the new wing. This save a lot of sanding to get a consistent trailing edge! I wasn't sure how to proceed next because no airfoil sections were given in the plans. I spent hours studying photos and eventually concluded that a reasonable approximation could be made by carefully mating the wing to the body and duplicating the way the wing is faired into the existing and mostly unmodified fuselage. Also there is a very nice photo on the NASA web site that clearly shows the reverse camber of the hypercritical airfoil. These contours were built up using of all things, Bondo! I'm very familiar with Bondo because years ago I used to paint cars. It seemed ideal - quick to cure, easy to sand, and cheap. Unfortunately, I found out it doesn't adhere very well to styrene. Because of this Bondo doesn't feather edge at all when used with plastic. In a few places I super glued it back down where it started to come loose. So while I was able to rough out the shape very quickly, the wing took four heavy coats of car primer sanded between coats before it even began to look okay. When the basic shape looked good it was time to add details to the wing. The fairings were carved from block styrene and faired in with putty. Slots were cut with a razor saw to receive wing fences. The control surfaces were cut in with a razor saw and their leading edges beveled slightly. Recesses for the semi conformal missiles were cut with a Dremel tool. Ordnance pylons were made from styrene, with shackles from the parts box. Wing tanks and pylons were modified as per the IPMS article. The sidewinder launch rails were cut from the kit wings and glued on the new wingtips. F-16s have probably more removable panels per acre of aluminum than any other a/c out there, and Hasegawa did an excellent job with the intricate recessed detail on the model. I hoped that I would be able to save most of this detail, only having to rescribe the new wing and the "plug" areas. However by the time all the sanding and filling was done much of the original scribing was wiped out. Now, I've rescribed a couple of kits before, mostly straight lines and a few panels from templates, but the access panels on the back were like skipping from the easy freshman introductory class to some unfathomably difficult, weed out all but the most sadomasochistic, dedicated, graduate level course in scribing plastic! I had to make my own templates, and more than a few had to be filled with superglue, sanded and rescribed until they looked good enough. This model did enough damage that I am finally forced to use an Optivisor. When I look at the palms of my hands, I start thinking of how to reproduce the detail... Enough of that - if you're still with me this far then you understand! Back to the model. The F-16XLs had FSD cockpits essentially like F-16As, so a Black Box cockpit was used. The Aires resin exhaust looks great, but the aft fuselage piece they give you is a little smaller than the kit so it was carefully faired in. The Hasegawa kit does not have complete intake ducting and ends in a blank wall. The Seamless Suckers intake solves this problem, but adds some of its own. With care it can be made to fit okay but pinholes need to be filled, including the inside of the air intake. The shapes of the intake need to be sanded a little to square them up. MV lenses were used for landing lights, and brass rod with the end of a pin made up the boom. Various antennae were made from plastic card. The light on the top of the tail was cut off and replaced with one carved from plastic. Sidewinders and bombs came from the Hasegawa weapons sets. |

-tn.jpg)

-tn.jpg)

| Most of the markings on the XLs were standard F-l6 markings so they are easy to borrow from other sheets. As a result I have two Two Bobs (no pun) decal sheets that are missing the needed decals. The markings unique to the XL are the ones on the tail, and the data plate. For the ones on the tail I scanned the Monogram markings into Corel Photo Paint, cropped, and then imported into Corel Draw. I couldn't just print them at 150% because the Monogram decals had errors of both font and size and when enlarged generally looked inconsistent. I used the scan as a guide to help me draw new artwork. The "F-16XL" logo was redrawn one letter at a time. I used guidelines to help ensure alignment. The "General Dynamics" was in the wrong font on the Monogram decals, and I didn't have the correct font so I choose one that was close and modified the letters that were different from photos. The same was done for the serial numbers. The data plate is hardly noticeable, but the Two Bobs data plate looked good except that it of course read "F-16C" and had the wrong serial for either XL. Again I scanned in Corel, but this time I simply typed a new data plate in Arial font and resized. I found that a simple font works best at this small size. The new artwork was printed on plain paper, cut out and taped to the model to test for size. When it looked good, Al printed them to decal paper on his ALPS printer. For a final finish I wanted to duplicate the look of the real a/c which had dull camouflage colors but some gloss on a red, white and blue scheme. After decaling was done, the whole model was given a coat of semi-gloss. Then Post-It notes were used to mask off the areas to remain semigloss before spraying the rest of the model with Testors Dullcoat. Well it was a bit of a stretch, and I became a bit obsessed near the end. I can definitely tell you that my wife is glad that it is finished. More like laid to rest. Is it a prefect model? No, the wing fairings look a bit large compared to photos, even after following the plans. More detail could be added, and some areas, like the airfoil had to be deduced (read: guesstimated). However it's built and it looks good to me on the shelf. Now, if I can only find some plans for the X31... |

|

-tn.jpg)

-tn.jpg)