Making a 1/48 Albatros D.III (Oeffag) from the Eduard Kit |  | I had wanted to build a blunt nosed Albatros DIII for some time. I'm sure that Eduard will eventually get around to releasing one in their wonderful WWI series, but I decided to convert their regular 1/48 kit now. It's really a fairly simple procedure. This article will jump right into how to do that conversion, as well as point out some pitfalls. I'm not going to spend any time discussing the aircraft although it does have an interesting history; the same aircraft can be put in Czech markings (and camouflage) with the heart/arrow of Navatril. At the end of this article, there are several links to invaluable photographs and illustrations.  After doing parts clean up, which was a breeze, I built up the interior. Since I had the basic kit rather than the Profipack, I didn't get the cool photoetch for the details. For the seat harness, I looked and looked in my stash to find something likely. I was toying with the idea of cannibalizing another kit, when I decided to do it the old way. I cut a strip of lead foil on my paper cutter and fashioned a harness out of that. In order to add the metal rings near the shoulders, I used bits of photoetch (where wire would have worked just as well). In the end, I was very pleased with how it turned out. I also used a photoetch seatback , a dial from Copper State Models, and lead wire connected to the buttons on the joystick. Otherwise, the interior was fairly stock. After doing parts clean up, which was a breeze, I built up the interior. Since I had the basic kit rather than the Profipack, I didn't get the cool photoetch for the details. For the seat harness, I looked and looked in my stash to find something likely. I was toying with the idea of cannibalizing another kit, when I decided to do it the old way. I cut a strip of lead foil on my paper cutter and fashioned a harness out of that. In order to add the metal rings near the shoulders, I used bits of photoetch (where wire would have worked just as well). In the end, I was very pleased with how it turned out. I also used a photoetch seatback , a dial from Copper State Models, and lead wire connected to the buttons on the joystick. Otherwise, the interior was fairly stock.

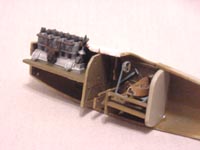

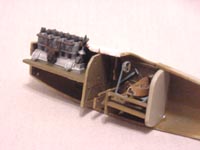

Building the engine is very straight-forward. I used many washes of Testor's Metallizers to get the look that I wanted of it. Instead of a collector for the exhaust, though, this aircraft had exhaust stacks. I drilled holes into each cylinder head to take regular household copper wire. I first stripped some copper wire and kept both the casing and the wire. I cut six bits of casing to the length of each stack and dressed the ends with a 45 degree angle. Then I glued a short (a little over half the length of the stacks) copper wire into each of those holes and adjusted them to make sure they were all aligned. I then slipped the dressed casings over each wire and CA glued them in place. When they were all in place, I painted the stacks with Testor's Metallizer Anodized Steel, Burnt Iron, then with Floquil Rust. Most people are surprised you can make these things out of vinyl tubing. Building the engine is very straight-forward. I used many washes of Testor's Metallizers to get the look that I wanted of it. Instead of a collector for the exhaust, though, this aircraft had exhaust stacks. I drilled holes into each cylinder head to take regular household copper wire. I first stripped some copper wire and kept both the casing and the wire. I cut six bits of casing to the length of each stack and dressed the ends with a 45 degree angle. Then I glued a short (a little over half the length of the stacks) copper wire into each of those holes and adjusted them to make sure they were all aligned. I then slipped the dressed casings over each wire and CA glued them in place. When they were all in place, I painted the stacks with Testor's Metallizer Anodized Steel, Burnt Iron, then with Floquil Rust. Most people are surprised you can make these things out of vinyl tubing.  .............. ..............

I then had to think about make modifications to the fuselage in order to build the Oeffag Albatros. On a German Albatros, the engine cut-out goes nearly all the way back to the cockpit, and the Spandau machine guns sit on a brace in that opening. On the Austrian machine, there are two Schwarzlose machine guns buried in the fuselage and the opening doesn't go back much past the engine. I had to consider two things: breeches for the Schwarzloses and closing the gap. Both turned out to be pretty easy tasks. Breeches: I decided to glue the breeches in early and slide the gun barrels in at the very end. I took the basic shapes of the gun breeches from the Glencoe kit and sanded and filled until they looked about right and attached them to the firewall.  . . . .

Engine opening: I used a scalpel to cut at the opening to square it off; that way it would be easier to fit an insert. I put inserts into each fuselage half then filled and sanded. There are pictures on this page to illustrate this stage. I filled and smoothed over any irregularities in the fuselage after zipping it up, then rescribed where necessary. I also removed some molded in details; the centerline access hatches under the fuselage didn't exactly mate across the seam, nor did the harness between the landing gear attachment points to the fuselage. I sanded those areas clean and replaced the detail later.

Earlier on, I had filled the spinner with Squadron Green Stuff and now I sanded the gluing edge totally flat and glued that to the fuselage. I shaped the nose with files and sandpaper. The nose of the Oeffag DIII is blunter than the spinner on the German DIII but it's not that far to go. I eventually drilled a hole in the middle of the nose to take the propellor and attached that after rigging was complete. I'm very happy with my propellor, by the way; I first painted it Floquil Dark Earth (British) then streaked it with Floquil Dark Brown (Italian). I then washed that with Floquil Dark Earth to mute the brown a bit. (NB, it would be incorrect to use very dark and very light streaks; in all the pictures of these aircraft, the propellors showed very muted grain if any.) I gloss coated then applied the Axial decals. I finished by putting Earlier on, I had filled the spinner with Squadron Green Stuff and now I sanded the gluing edge totally flat and glued that to the fuselage. I shaped the nose with files and sandpaper. The nose of the Oeffag DIII is blunter than the spinner on the German DIII but it's not that far to go. I eventually drilled a hole in the middle of the nose to take the propellor and attached that after rigging was complete. I'm very happy with my propellor, by the way; I first painted it Floquil Dark Earth (British) then streaked it with Floquil Dark Brown (Italian). I then washed that with Floquil Dark Earth to mute the brown a bit. (NB, it would be incorrect to use very dark and very light streaks; in all the pictures of these aircraft, the propellors showed very muted grain if any.) I gloss coated then applied the Axial decals. I finished by putting  a thin coat of Future over it all; it looks like varnished wood to me. a thin coat of Future over it all; it looks like varnished wood to me. It was at this point that I studied the rigging chart in the instructions and drilled pilot holes for all the rigging. This would be very difficult to do with the upper wing or the rudder in place. Having the holes is a life saver; it not only gives you more surface area to glue. It also lets you measure the line a little long and push it into the hole until it's taut.  I built the Eduard Albatros DII a couple months ago, and it's nearly the same kit except for the wing. With that in mind, it helped me get past some problem areas in it. On the DII, I recalled having a terrible time trying to connect the radiator hoses from the upper wing to the engine once the upper wing was already in place. With that in mind, I decided to simplify that procedure on the DIII. I drilled one hole in the engine and one behind the engine, and enlarged the sockets in the upper wing. I used copper wire instead of using the kit pieces; it allows more play and is much stronger than plastic. I first attached a wire to the fuselage (it was also useful to hang the model when painting). When it was time to attach the upper wing, I just had to I built the Eduard Albatros DII a couple months ago, and it's nearly the same kit except for the wing. With that in mind, it helped me get past some problem areas in it. On the DII, I recalled having a terrible time trying to connect the radiator hoses from the upper wing to the engine once the upper wing was already in place. With that in mind, I decided to simplify that procedure on the DIII. I drilled one hole in the engine and one behind the engine, and enlarged the sockets in the upper wing. I used copper wire instead of using the kit pieces; it allows more play and is much stronger than plastic. I first attached a wire to the fuselage (it was also useful to hang the model when painting). When it was time to attach the upper wing, I just had to  cut that line short and align it; it was already in position. I also recalled another problem area on the DII; the upper wing was difficult to attach as the sockets to take the wing struts and cabane struts were not quite large enough. Dry fitting is a great idea, and to ease the whole process on this one, I enlarged the sockets for the strut attachment points. That simple expedient paid huge dividends later. cut that line short and align it; it was already in position. I also recalled another problem area on the DII; the upper wing was difficult to attach as the sockets to take the wing struts and cabane struts were not quite large enough. Dry fitting is a great idea, and to ease the whole process on this one, I enlarged the sockets for the strut attachment points. That simple expedient paid huge dividends later. In all the pictures and illustrations that I've seen of this aircraft, the tail skid should be the length of the fin-like structure it's attached to while the kit part is about 2/3 the length. I glued an extension onto the kit skid; it was a very simple modification. Then I removed part of the fin so the tail skid is would fit the length.  With the landing gear, the Eduard kit instructs you to glue the axle directly to the langing gear strut. It doesn't look right; there has to be some other structure to it. I wasn't able to find photographs of what the DIII attachment point for the gear looks like, but a lot of aircraft of that era used a sort of bungee cord. I just wrapped some kite string between the axle and strut and wound it through a couple times. I secured it with CA glue and washed it with dirty thinner; it makes sense now. With the landing gear, the Eduard kit instructs you to glue the axle directly to the langing gear strut. It doesn't look right; there has to be some other structure to it. I wasn't able to find photographs of what the DIII attachment point for the gear looks like, but a lot of aircraft of that era used a sort of bungee cord. I just wrapped some kite string between the axle and strut and wound it through a couple times. I secured it with CA glue and washed it with dirty thinner; it makes sense now. Painting  I did all the painting and decalling prior to attaching the upper wing. I first masked the engine and the cockpit. Then I sprayed the underside of the horizontal stabilizers and both wings Floquil Panzer interior buff to represent linen. Then I masked the buff and sprayed Floquil Italian Sand. I then freehand airbrushed Floquil British dark green in a mottle scheme. I then sprayed a clear gloss coat over the whole model; I decided to experiment with Testor's Metallizer sealer on the recommendation from a friend. As a gloss coat for decalling, it's fairly effective but I had a difficult time cleaning my airbrush after. Maybe I should have cleaned with lacquer thinner. I did all the painting and decalling prior to attaching the upper wing. I first masked the engine and the cockpit. Then I sprayed the underside of the horizontal stabilizers and both wings Floquil Panzer interior buff to represent linen. Then I masked the buff and sprayed Floquil Italian Sand. I then freehand airbrushed Floquil British dark green in a mottle scheme. I then sprayed a clear gloss coat over the whole model; I decided to experiment with Testor's Metallizer sealer on the recommendation from a friend. As a gloss coat for decalling, it's fairly effective but I had a difficult time cleaning my airbrush after. Maybe I should have cleaned with lacquer thinner.  Markings Markings I decided to purchase a very cheap old Glencoe kit and use its decals. I thought I was saving a few bucks as the other choice was to purchase a US$20 decal sheet with reference booklet produced by Blue Rider. In the end, however, the Glencoe decals turned out to be very difficult to use; they had a lot of whitish glue residue on them, they didn't really conform well to surface detail, and the carrier film was too thick. To their credit, however, they were in perfect register. If you do use these decals, make sure to trim the carrier film all the way to the image; the carrier film is quite thick and is visible even under several clear coats.  I used lots of Solvaset to get the decals to snuggle down and it appeared that they were responding well to it. The next day, however, I found that far from snuggling, the decals had a lot of silvering and even a little peeling. This became even more apparent after spraying Dull-Cote, so it was cause for some amount of fretting to get them to look acceptable. I used lots of Solvaset to get the decals to snuggle down and it appeared that they were responding well to it. The next day, however, I found that far from snuggling, the decals had a lot of silvering and even a little peeling. This became even more apparent after spraying Dull-Cote, so it was cause for some amount of fretting to get them to look acceptable. It was after decalling that I took the partially complete model to an IPMS Seattle meeting and asked for critique on it so far. The one comment that I heard was that this aircraft had a smudged camouflage rather than an airbrushed scheme. Mine was too neat. Even having decalled, I went back and smudged it here and there with Italian Sand to get it to look a little messier. Although I miss how neat it was earlier, I've learned to appreciate the random messiness of the smudged camouflage pattern.  After all the painting and decalling was complete, I finally attached the upper wing. I started with the outboard struts; I attached them perpendicular to the wing and waited for the CA glue to set slightly but not completely. Then I fudged the wing into place and glued it to the lower wing. After I was satisfied that the wing was aligned in every way, I touched those strut attachment points with accelerator. With the upper wing pretty secure, it was quick work to slip the cabane struts into place. This model is engineered so well that you can get away with that kind of approach; on a lesser kit, a jig of some sort would be in order. After all the painting and decalling was complete, I finally attached the upper wing. I started with the outboard struts; I attached them perpendicular to the wing and waited for the CA glue to set slightly but not completely. Then I fudged the wing into place and glued it to the lower wing. After I was satisfied that the wing was aligned in every way, I touched those strut attachment points with accelerator. With the upper wing pretty secure, it was quick work to slip the cabane struts into place. This model is engineered so well that you can get away with that kind of approach; on a lesser kit, a jig of some sort would be in order. I finally replaced the access hatches under the fuselage with some photoetch ones I pulled out of another kit. I'm sure I can replace them somehow. As for the metal harness between the landing gear struts, I just drilled some tiny holes and threaded stainless steel wire through and secured them with CA glue. Rigging  I started by attaching the landing gear rigging, then worked on the wings. Rigging is a lot simpler if you can hold the model in place and can position it for best access and best light; a Panavise is the ultimate tool for that job. Having drilled the pilotholes for the rigging, it was fairly simple to put it all in place. There are a couple of complications though; two of the holes required inserting more than one line. One hole in the fuselage has two lines going to the upper wing outboard. There is another hole in each lower wing which require inserting three lines; two to the upper wing cabane strut point and one for the drag line. There is a picture on this page illustrating that process. I started by attaching the landing gear rigging, then worked on the wings. Rigging is a lot simpler if you can hold the model in place and can position it for best access and best light; a Panavise is the ultimate tool for that job. Having drilled the pilotholes for the rigging, it was fairly simple to put it all in place. There are a couple of complications though; two of the holes required inserting more than one line. One hole in the fuselage has two lines going to the upper wing outboard. There is another hole in each lower wing which require inserting three lines; two to the upper wing cabane strut point and one for the drag line. There is a picture on this page illustrating that process. Conclusion  This is an excellent kit; I can find very little to criticize on it. Older decals, like the ones I used, that are not high quality may cost more in time than would have been spent on better quality decals. Decals are also applied when you've already invested a lot of time in the kit; it's better to see it through. As for conversions, this was an easy one; if you've never done a conversion, this would be a great one to start. It's not that intimidating and the kit is fabulous. This is an excellent kit; I can find very little to criticize on it. Older decals, like the ones I used, that are not high quality may cost more in time than would have been spent on better quality decals. Decals are also applied when you've already invested a lot of time in the kit; it's better to see it through. As for conversions, this was an easy one; if you've never done a conversion, this would be a great one to start. It's not that intimidating and the kit is fabulous. Links and References |

|

After doing parts clean up, which was a breeze, I built up the interior. Since I had the basic kit rather than the Profipack, I didn't get the cool photoetch for the details. For the seat harness, I looked and looked in my stash to find something likely. I was toying with the idea of cannibalizing another kit, when I decided to do it the old way. I cut a strip of lead foil on my paper cutter and fashioned a harness out of that. In order to add the metal rings near the shoulders, I used bits of photoetch (where wire would have worked just as well). In the end, I was very pleased with how it turned out. I also used a photoetch seatback , a dial from Copper State Models, and lead wire connected to the buttons on the joystick. Otherwise, the interior was fairly stock.

After doing parts clean up, which was a breeze, I built up the interior. Since I had the basic kit rather than the Profipack, I didn't get the cool photoetch for the details. For the seat harness, I looked and looked in my stash to find something likely. I was toying with the idea of cannibalizing another kit, when I decided to do it the old way. I cut a strip of lead foil on my paper cutter and fashioned a harness out of that. In order to add the metal rings near the shoulders, I used bits of photoetch (where wire would have worked just as well). In the end, I was very pleased with how it turned out. I also used a photoetch seatback , a dial from Copper State Models, and lead wire connected to the buttons on the joystick. Otherwise, the interior was fairly stock. Building the engine is very straight-forward. I used many washes of Testor's Metallizers to get the look that I wanted of it. Instead of a collector for the exhaust, though, this aircraft had exhaust stacks. I drilled holes into each cylinder head to take regular household copper wire. I first stripped some copper wire and kept both the casing and the wire. I cut six bits of casing to the length of each stack and dressed the ends with a 45 degree angle. Then I glued a short (a little over half the length of the stacks) copper wire into each of those holes and adjusted them to make sure they were all aligned. I then slipped the dressed casings over each wire and CA glued them in place. When they were all in place, I painted the stacks with Testor's Metallizer Anodized Steel, Burnt Iron, then with Floquil Rust. Most people are surprised you can make these things out of vinyl tubing.

Building the engine is very straight-forward. I used many washes of Testor's Metallizers to get the look that I wanted of it. Instead of a collector for the exhaust, though, this aircraft had exhaust stacks. I drilled holes into each cylinder head to take regular household copper wire. I first stripped some copper wire and kept both the casing and the wire. I cut six bits of casing to the length of each stack and dressed the ends with a 45 degree angle. Then I glued a short (a little over half the length of the stacks) copper wire into each of those holes and adjusted them to make sure they were all aligned. I then slipped the dressed casings over each wire and CA glued them in place. When they were all in place, I painted the stacks with Testor's Metallizer Anodized Steel, Burnt Iron, then with Floquil Rust. Most people are surprised you can make these things out of vinyl tubing. Earlier on, I had filled the spinner with Squadron Green Stuff and now I sanded the gluing edge totally flat and glued that to the fuselage. I shaped the nose with files and sandpaper. The nose of the Oeffag DIII is blunter than the spinner on the German DIII but it's not that far to go. I eventually drilled a hole in the middle of the nose to take the propellor and attached that after rigging was complete. I'm very happy with my propellor, by the way; I first painted it Floquil Dark Earth (British) then streaked it with Floquil Dark Brown (Italian). I then washed that with Floquil Dark Earth to mute the brown a bit. (NB, it would be incorrect to use very dark and very light streaks; in all the pictures of these aircraft, the propellors showed very muted grain if any.) I gloss coated then applied the Axial decals. I finished by putting

Earlier on, I had filled the spinner with Squadron Green Stuff and now I sanded the gluing edge totally flat and glued that to the fuselage. I shaped the nose with files and sandpaper. The nose of the Oeffag DIII is blunter than the spinner on the German DIII but it's not that far to go. I eventually drilled a hole in the middle of the nose to take the propellor and attached that after rigging was complete. I'm very happy with my propellor, by the way; I first painted it Floquil Dark Earth (British) then streaked it with Floquil Dark Brown (Italian). I then washed that with Floquil Dark Earth to mute the brown a bit. (NB, it would be incorrect to use very dark and very light streaks; in all the pictures of these aircraft, the propellors showed very muted grain if any.) I gloss coated then applied the Axial decals. I finished by putting  a thin coat of Future over it all; it looks like varnished wood to me.

a thin coat of Future over it all; it looks like varnished wood to me.  I built the Eduard Albatros DII a couple months ago, and it's nearly the same kit except for the wing. With that in mind, it helped me get past some problem areas in it. On the DII, I recalled having a terrible time trying to connect the radiator hoses from the upper wing to the engine once the upper wing was already in place. With that in mind, I decided to simplify that procedure on the DIII. I drilled one hole in the engine and one behind the engine, and enlarged the sockets in the upper wing. I used copper wire instead of using the kit pieces; it allows more play and is much stronger than plastic. I first attached a wire to the fuselage (it was also useful to hang the model when painting). When it was time to attach the upper wing, I just had to

I built the Eduard Albatros DII a couple months ago, and it's nearly the same kit except for the wing. With that in mind, it helped me get past some problem areas in it. On the DII, I recalled having a terrible time trying to connect the radiator hoses from the upper wing to the engine once the upper wing was already in place. With that in mind, I decided to simplify that procedure on the DIII. I drilled one hole in the engine and one behind the engine, and enlarged the sockets in the upper wing. I used copper wire instead of using the kit pieces; it allows more play and is much stronger than plastic. I first attached a wire to the fuselage (it was also useful to hang the model when painting). When it was time to attach the upper wing, I just had to  cut that line short and align it; it was already in position. I also recalled another problem area on the DII; the upper wing was difficult to attach as the sockets to take the wing struts and cabane struts were not quite large enough. Dry fitting is a great idea, and to ease the whole process on this one, I enlarged the sockets for the strut attachment points. That simple expedient paid huge dividends later.

cut that line short and align it; it was already in position. I also recalled another problem area on the DII; the upper wing was difficult to attach as the sockets to take the wing struts and cabane struts were not quite large enough. Dry fitting is a great idea, and to ease the whole process on this one, I enlarged the sockets for the strut attachment points. That simple expedient paid huge dividends later. With the landing gear, the Eduard kit instructs you to glue the axle directly to the langing gear strut. It doesn't look right; there has to be some other structure to it. I wasn't able to find photographs of what the DIII attachment point for the gear looks like, but a lot of aircraft of that era used a sort of bungee cord. I just wrapped some kite string between the axle and strut and wound it through a couple times. I secured it with CA glue and washed it with dirty thinner; it makes sense now.

With the landing gear, the Eduard kit instructs you to glue the axle directly to the langing gear strut. It doesn't look right; there has to be some other structure to it. I wasn't able to find photographs of what the DIII attachment point for the gear looks like, but a lot of aircraft of that era used a sort of bungee cord. I just wrapped some kite string between the axle and strut and wound it through a couple times. I secured it with CA glue and washed it with dirty thinner; it makes sense now. I did all the painting and decalling prior to attaching the upper wing. I first masked the engine and the cockpit. Then I sprayed the underside of the horizontal stabilizers and both wings Floquil Panzer interior buff to represent linen. Then I masked the buff and sprayed Floquil Italian Sand. I then freehand airbrushed Floquil British dark green in a mottle scheme. I then sprayed a clear gloss coat over the whole model; I decided to experiment with Testor's Metallizer sealer on the recommendation from a friend. As a gloss coat for decalling, it's fairly effective but I had a difficult time cleaning my airbrush after. Maybe I should have cleaned with lacquer thinner.

I did all the painting and decalling prior to attaching the upper wing. I first masked the engine and the cockpit. Then I sprayed the underside of the horizontal stabilizers and both wings Floquil Panzer interior buff to represent linen. Then I masked the buff and sprayed Floquil Italian Sand. I then freehand airbrushed Floquil British dark green in a mottle scheme. I then sprayed a clear gloss coat over the whole model; I decided to experiment with Testor's Metallizer sealer on the recommendation from a friend. As a gloss coat for decalling, it's fairly effective but I had a difficult time cleaning my airbrush after. Maybe I should have cleaned with lacquer thinner. Markings

Markings I used lots of Solvaset to get the decals to snuggle down and it appeared that they were responding well to it. The next day, however, I found that far from snuggling, the decals had a lot of silvering and even a little peeling. This became even more apparent after spraying Dull-Cote, so it was cause for some amount of fretting to get them to look acceptable.

I used lots of Solvaset to get the decals to snuggle down and it appeared that they were responding well to it. The next day, however, I found that far from snuggling, the decals had a lot of silvering and even a little peeling. This became even more apparent after spraying Dull-Cote, so it was cause for some amount of fretting to get them to look acceptable. After all the painting and decalling was complete, I finally attached the upper wing. I started with the outboard struts; I attached them perpendicular to the wing and waited for the CA glue to set slightly but not completely. Then I fudged the wing into place and glued it to the lower wing. After I was satisfied that the wing was aligned in every way, I touched those strut attachment points with accelerator. With the upper wing pretty secure, it was quick work to slip the cabane struts into place. This model is engineered so well that you can get away with that kind of approach; on a lesser kit, a jig of some sort would be in order.

After all the painting and decalling was complete, I finally attached the upper wing. I started with the outboard struts; I attached them perpendicular to the wing and waited for the CA glue to set slightly but not completely. Then I fudged the wing into place and glued it to the lower wing. After I was satisfied that the wing was aligned in every way, I touched those strut attachment points with accelerator. With the upper wing pretty secure, it was quick work to slip the cabane struts into place. This model is engineered so well that you can get away with that kind of approach; on a lesser kit, a jig of some sort would be in order. I started by attaching the landing gear rigging, then worked on the wings. Rigging is a lot simpler if you can hold the model in place and can position it for best access and best light; a Panavise is the ultimate tool for that job. Having drilled the pilotholes for the rigging, it was fairly simple to put it all in place. There are a couple of complications though; two of the holes required inserting more than one line. One hole in the fuselage has two lines going to the upper wing outboard. There is another hole in each lower wing which require inserting three lines; two to the upper wing cabane strut point and one for the drag line. There is a picture on this page illustrating that process.

I started by attaching the landing gear rigging, then worked on the wings. Rigging is a lot simpler if you can hold the model in place and can position it for best access and best light; a Panavise is the ultimate tool for that job. Having drilled the pilotholes for the rigging, it was fairly simple to put it all in place. There are a couple of complications though; two of the holes required inserting more than one line. One hole in the fuselage has two lines going to the upper wing outboard. There is another hole in each lower wing which require inserting three lines; two to the upper wing cabane strut point and one for the drag line. There is a picture on this page illustrating that process. This is an excellent kit; I can find very little to criticize on it. Older decals, like the ones I used, that are not high quality may cost more in time than would have been spent on better quality decals. Decals are also applied when you've already invested a lot of time in the kit; it's better to see it through. As for conversions, this was an easy one; if you've never done a conversion, this would be a great one to start. It's not that intimidating and the kit is fabulous.

This is an excellent kit; I can find very little to criticize on it. Older decals, like the ones I used, that are not high quality may cost more in time than would have been spent on better quality decals. Decals are also applied when you've already invested a lot of time in the kit; it's better to see it through. As for conversions, this was an easy one; if you've never done a conversion, this would be a great one to start. It's not that intimidating and the kit is fabulous.