The Ship's Camel:

Building the Eduard Sopwith Camel 2F1 in 1/48 Scale

|

|

History

A brief history of the Sopwith Camel 2F1 is included in the First

Look Preview in the February Internet Modeler, so I will just add

a few words about the particular aircraft I chose to model. As mentioned

in the preview, the kit I received is a pre-production test shot, which

came without instructions, decals, or a box with boxart. After some deliberation

I chose to build the kit in the markings of a blue and white checkered

aircraft as flown by Captain Bernard Arthur Smart from HMS Furious in

1918. This aircraft was one of seven launched from HMS Furious on July

19, 1918 as part of the first carrier air strike in history, the target

being the Zeppelin base at Tondern. The aircraft were specially configured

for the mission with bomb racks and bomb sights, and the Lewis guns were

left behind to save weight. The raid was a success with two Zeppelins

being destroyed in their sheds by the 50-pound bombs dropped by the Camels.

Only two of the Camels managed to return to Furious, one of which was

Smart's aircraft. Captain Smart was awarded the Distinguished Service

Order for this exploit.

Construction

As

mentioned the kit came without instructions (Bah, who needs instructions,

anyway?). Luckily I already had an example of the Camel F1 kit, so the

instructions from this kit came in very handy during the build. I also

happened to have the Windsock Datafile for the 2F1, which proved indispensable

while I was trying to puzzle together the various details in this kit.

This Datafile also has a very fine profile of Smart's aircraft on the

cover by Ray Rimell and drawings within by Ian Stair. As

mentioned the kit came without instructions (Bah, who needs instructions,

anyway?). Luckily I already had an example of the Camel F1 kit, so the

instructions from this kit came in very handy during the build. I also

happened to have the Windsock Datafile for the 2F1, which proved indispensable

while I was trying to puzzle together the various details in this kit.

This Datafile also has a very fine profile of Smart's aircraft on the

cover by Ray Rimell and drawings within by Ian Stair.

Overall fit of the parts is excellent. Curiously there was a very slight

ridge of material along the edges of many of the parts, which has to be

removed to ensure a good fit. This was easily accomplished with a few

swipes with a sanding stick in most cases. Many of the smaller parts are

very fine and delicate, and require great care while removing them from

the sprues to prevent breakage.

I began by preparing the fuselage halves to include the details peculiar

to the 2F1. This meant scribing a line where the fuselage separates as

well as filling in the side step and moving it forward of this line. A

hole was drilled in the proper location for the external elevator bellcranks

as per the drawings in the Datafile. As the 2F1 normally carried only

one Vickers, the ejector port on the right side of the fuselage needs

to be filled in. The kit provides a part to plug this hole, which when

cemented and sanded flush does the job.

Construction

of the cockpit then began in earnest. The instrument panel and other interior

wood structures were prepared by painting them a wood color. Everyone

has their favorite method of recreating wood with paints. My method involves

painting the area first with Tamiya acrylic XF-59 Desert Yellow thinned

with Future. When this is dry a thin streaky coat of Testors ModelMaster

Burnt Sienna or Raw Umber enamel is applied with a Filbert tipped brush

to impart a wood grain effect. Then if desired a seal coat of Gunze Clear

Orange and/or Clear Yellow thinned with Future is airbrushed on in very

thin coats to get the desired varnished effect. Sometimes just a coat

of clear is all that is required. Construction

of the cockpit then began in earnest. The instrument panel and other interior

wood structures were prepared by painting them a wood color. Everyone

has their favorite method of recreating wood with paints. My method involves

painting the area first with Tamiya acrylic XF-59 Desert Yellow thinned

with Future. When this is dry a thin streaky coat of Testors ModelMaster

Burnt Sienna or Raw Umber enamel is applied with a Filbert tipped brush

to impart a wood grain effect. Then if desired a seal coat of Gunze Clear

Orange and/or Clear Yellow thinned with Future is airbrushed on in very

thin coats to get the desired varnished effect. Sometimes just a coat

of clear is all that is required.

The fabric areas of the interior were painted Gunze H85 Sail Color acrylic,

and the bare metal areas Citadel Chain Mail acrylic. All the acrylic paints

that were sprayed were thinned with Future to give a smooth finish and

to enhance strength and adhesion.

The instrument bezels were picked out with Testors ModelMaster Acryl

Interior Black paint, and Reheat instrument dials were used for the instrument

faces. A drop of Future on each then  represented

the glass face. The seat comes as either a solid plastic part, or as a

base with a rim for a photoetched weaved back which is included in the

Profipack kits. The F1 kit I have comes with a set of decals to recreate

the weave for the solid seat, so I decided to try them. I painted the

seat in the wood effect as described, and then applied the decals. I thought

the contrast of the black decal and the seat was too stark so I applied

a thin transparent layer of Desert Yellow over it to mute it down. Seatbelts

were provided from the Eduard WWI RFC Seatbelt set, which were painted

Citadel Bleached Bone, a good webbing color. The fuel tanks behind the

seat are a nice touch. These were painted with Citadel Chain Mail and

straps added with brown-painted clear decal film cut in narrow strips.

Some care is required to align the filler pipe on the main fuel tank with

the hole in the turtledeck. Mine did not line up, so I would suggest adding

the pipe after the fuselage is assembled. represented

the glass face. The seat comes as either a solid plastic part, or as a

base with a rim for a photoetched weaved back which is included in the

Profipack kits. The F1 kit I have comes with a set of decals to recreate

the weave for the solid seat, so I decided to try them. I painted the

seat in the wood effect as described, and then applied the decals. I thought

the contrast of the black decal and the seat was too stark so I applied

a thin transparent layer of Desert Yellow over it to mute it down. Seatbelts

were provided from the Eduard WWI RFC Seatbelt set, which were painted

Citadel Bleached Bone, a good webbing color. The fuel tanks behind the

seat are a nice touch. These were painted with Citadel Chain Mail and

straps added with brown-painted clear decal film cut in narrow strips.

Some care is required to align the filler pipe on the main fuel tank with

the hole in the turtledeck. Mine did not line up, so I would suggest adding

the pipe after the fuselage is assembled.

The 2F1 was powered by the Bentley B. R. I, but the kit only provides

the Clerget. I decided to  use

the Clerget as provided due to time constraints but the modeler can modify

the kit engine to look more like a Bentley if desired. The parts for the

pushrods are very delicate and fiddly, and I broke several when removing

them from the sprue. The missing broken ones were replaced with stretched

sprue. On future Camel builds I think I will replace all the push rods

with sprue from the outset, as it looks cleaner. The finished engine was

painted gunmetal and given a wash of flat black, then mounted on the firewall

with the retaining pin provided. This allows the engine to turn freely

on the firewall, as a rotary should. use

the Clerget as provided due to time constraints but the modeler can modify

the kit engine to look more like a Bentley if desired. The parts for the

pushrods are very delicate and fiddly, and I broke several when removing

them from the sprue. The missing broken ones were replaced with stretched

sprue. On future Camel builds I think I will replace all the push rods

with sprue from the outset, as it looks cleaner. The finished engine was

painted gunmetal and given a wash of flat black, then mounted on the firewall

with the retaining pin provided. This allows the engine to turn freely

on the firewall, as a rotary should.

All the various interior subassemblies were now brought together and

the fuselage halves cemented together. The joint was sanded smooth, but

I obliterated some of the sunken fabric detail on the turtle deck while

trying to eliminate some stubborn sprue gate areas. The lower wing and

firewall  was

mounted to the fuselage after a very slight amount of trimming of the

joining areas. A very good fit resulted. I used just a very small amount

of filler to eliminate the lower joints. As the engine was mounted on

the firewall that formed part of the fuselage structure I decided to install

the cowling to protect the vulnerable engine and to facilitate painting

of the blue and white checkers later. Here I ran into a bit of trouble

as the cowling was just slightly narrower than the fuselage and sat slightly

right of center. I trimmed and sanded the inside of the cowl on the right

side and trimmed the firewall on the left side, so that the cowl lined

up a little better, but it still was not perfect (Eduard is already aware

of this problem and are making the necessary corrections for the production

kit). One effect was that the inside of the cowl now fouled the engine

and would not allow it to turn. Oh well. The remaining joints were cleaned

up and a few areas filled in with Mr. Surfacer 500 where required. was

mounted to the fuselage after a very slight amount of trimming of the

joining areas. A very good fit resulted. I used just a very small amount

of filler to eliminate the lower joints. As the engine was mounted on

the firewall that formed part of the fuselage structure I decided to install

the cowling to protect the vulnerable engine and to facilitate painting

of the blue and white checkers later. Here I ran into a bit of trouble

as the cowling was just slightly narrower than the fuselage and sat slightly

right of center. I trimmed and sanded the inside of the cowl on the right

side and trimmed the firewall on the left side, so that the cowl lined

up a little better, but it still was not perfect (Eduard is already aware

of this problem and are making the necessary corrections for the production

kit). One effect was that the inside of the cowl now fouled the engine

and would not allow it to turn. Oh well. The remaining joints were cleaned

up and a few areas filled in with Mr. Surfacer 500 where required.

Finishing and Decals

I began painting the airframe by painting the blue and white checker

pattern on the nose. This was accomplished in three stages, first with

a coat of Testors ModelMaster Acryl Semi Gloss White  sprayed

over the entire area. When this was cured I masked off one row of squares

with Tamiya masking tape, then sprayed Testors ModelMaster Acryl French

Blue. When this was dry I then masked off the remaining rows of squares

and sprayed them blue as well. This involves a little extra effort but

the result is well worth the time spent. Once this was dry I masked off

the entire checkered area and prepared the model for the remaining colors. sprayed

over the entire area. When this was cured I masked off one row of squares

with Tamiya masking tape, then sprayed Testors ModelMaster Acryl French

Blue. When this was dry I then masked off the remaining rows of squares

and sprayed them blue as well. This involves a little extra effort but

the result is well worth the time spent. Once this was dry I masked off

the entire checkered area and prepared the model for the remaining colors.

The rudder and elevators have control horns molded on which I did not

like, so I trimmed them off and replaced them with photoetched horns from

the PART Horns and Turnbuckles set. The elevators' torque tube connecting

them is extremely thin and delicate, and despite all my efforts the elevator

assembly broke in two.

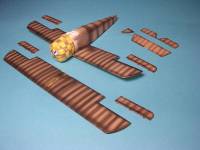

For some unknown reason the kit comes with ten ailerons, of which of

course only four are needed. These were cleaned up and control horns attached.

The control surfaces fit very well to their respective flying surfaces,

with a light press-fit in most cases.

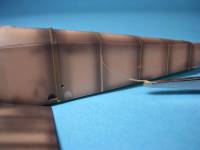

The

raised rib tape detail on the kit is fairly evident. Upon examining photos

of the real airplane this appears to be the case, so I left them as is.

The kit includes clear parts for the transparent wing inspection panels.

These were cemented in place after the insides of which were painted Burnt

Sienna to indicate the wood interior framework. These were then masked

off with Tamiya tape in preparation for painting. The

raised rib tape detail on the kit is fairly evident. Upon examining photos

of the real airplane this appears to be the case, so I left them as is.

The kit includes clear parts for the transparent wing inspection panels.

These were cemented in place after the insides of which were painted Burnt

Sienna to indicate the wood interior framework. These were then masked

off with Tamiya tape in preparation for painting.

The landing gear struts were assembled but I thought they looked a little

bare so I added bungee chord shock absorbers made from cotton thread fixed

with superglue. Unfortunately the main wheel double axle is molded into

the spreader. For a characteristic Sopwith "Sit" with the wheels

splayed out some modification would be required. Perhaps a pair of axles

of brass tubing or rod would be in order. I just decided to build them

as supplied and carry on. The wheel covers were painted Gunze Sail Color

and the tyres masked off with Tamiya tape cut in arcs with an Olpha compass

cutter. The tyres were then painted dark grey.

The color scheme applied would be the ubiquitous PC10 over Clear Doped

Linen (CDL). I decided to preshade some areas in order to break up the

potential monotony of the finish, and to  add

some depth and dimension. The upper surfaces were preshaded with black

and the lower surfaces preshaded with dark earth. I also masked off the

rib locations along the fuselage. The lower surfaces were then sprayed

with several light coats of Gunze 85 Sail Color, subtly allowing the preshading

to show through. The upper surfaces were sprayed in the same way with

Gunze H421 RLM 81 Braun Violet, as good a match for PC10 as any (PC10

could vary from olive drab to chocolate brown or anything in between).

I was quite happy with the final result. PC10 was also applied to the

landing gear strut assembly and to the interplane and cabane struts. The

little Rotherham pump on the right rear cabane was picked out with black

and drybrushed aluminum. The pump propeller was painted using the wood

method mentioned, as was the main propeller, with the hub detailed with

Citadel Boltgun Metal (The Citadel range of acrylic paints have some rather

bizarre names but they are among the finest acrylic paints I have used

to date). The wooden panels on the fuselage were painted wood as well

in the same manner. The masking tape came off the checkerboard and a few

areas touched up with a brush. The cockpit coaming was then painted Humbrol

Red Leather. add

some depth and dimension. The upper surfaces were preshaded with black

and the lower surfaces preshaded with dark earth. I also masked off the

rib locations along the fuselage. The lower surfaces were then sprayed

with several light coats of Gunze 85 Sail Color, subtly allowing the preshading

to show through. The upper surfaces were sprayed in the same way with

Gunze H421 RLM 81 Braun Violet, as good a match for PC10 as any (PC10

could vary from olive drab to chocolate brown or anything in between).

I was quite happy with the final result. PC10 was also applied to the

landing gear strut assembly and to the interplane and cabane struts. The

little Rotherham pump on the right rear cabane was picked out with black

and drybrushed aluminum. The pump propeller was painted using the wood

method mentioned, as was the main propeller, with the hub detailed with

Citadel Boltgun Metal (The Citadel range of acrylic paints have some rather

bizarre names but they are among the finest acrylic paints I have used

to date). The wooden panels on the fuselage were painted wood as well

in the same manner. The masking tape came off the checkerboard and a few

areas touched up with a brush. The cockpit coaming was then painted Humbrol

Red Leather.

This sample kit did not come with decals, so I had to go to another

source. I had the Aeromaster  sheet

48081 "Camels Part I" which were used. The markings on this

Camel are very simple, consisting of only white edged roundels on all

six locations and the rudder tricolor. These went on with no problems

after giving the areas a gloss coat of Future where they were to go. My

only complaint is that the blue is too dark in my opinion, RFC Roundel

Blue being quite a bit lighter during this period. When the decals were

in place and dry they were sealed with a coat of Future. A very light

wash of a thinned mixture of Testors Raw Umber and Flat Black enamels

was applied sparingly around the cowling, wing panel joints, and the wing

root areas. The wheels and tyres were weathered a bit heavier, as I thought

they would pick up a lot more grunge. When all was dry a few thin coats

of Testors Acryl Semi Gloss Clear was applied to kill the shine. sheet

48081 "Camels Part I" which were used. The markings on this

Camel are very simple, consisting of only white edged roundels on all

six locations and the rudder tricolor. These went on with no problems

after giving the areas a gloss coat of Future where they were to go. My

only complaint is that the blue is too dark in my opinion, RFC Roundel

Blue being quite a bit lighter during this period. When the decals were

in place and dry they were sealed with a coat of Future. A very light

wash of a thinned mixture of Testors Raw Umber and Flat Black enamels

was applied sparingly around the cowling, wing panel joints, and the wing

root areas. The wheels and tyres were weathered a bit heavier, as I thought

they would pick up a lot more grunge. When all was dry a few thin coats

of Testors Acryl Semi Gloss Clear was applied to kill the shine.

Final Assembly and Rigging

After examining the many photos in the Datafiles and elsewhere I could

not resist the temptation to add a few extra details to the model. These

included a pitot tube on the right forward interplane strut made out of

brass wire, a windscreen cut out of a sheet of  Evergreen

.010" clear styrene stock, and picquet rings made of brass bead wire

twisted into an eyelet. The Vickers gun as supplied in the kit was a little

bare so I added a photoetched cocking handle from a leftover Eduard Sopwith

Triplane set. Strangely the Vickers gun comes in two parts, presumably

to aid installation into the cowling, but I assembled this one and painted

it completely before installing it and it fit very well. The very delicate

Lewis gun and its unique Admiralty Top Plane Mounting was puzzled together

from the parts supplied with the kit and from examining available photos.

This was later mounted on the top wing so that it could swivel up and

down: A little finicky, but the final result was worth the effort. The

external elevator bellcranks were added as were the attaching fittings

for the fuselage joint made out of short lengths of Evergreen stock painted

black. Too late I realized there were lifting brackets on the top wing

center section, so I added these with some black decal film cut into tiny

triangles, but they are probably better made with thin card or brass sheet

stock. They still look OK, I think. Evergreen

.010" clear styrene stock, and picquet rings made of brass bead wire

twisted into an eyelet. The Vickers gun as supplied in the kit was a little

bare so I added a photoetched cocking handle from a leftover Eduard Sopwith

Triplane set. Strangely the Vickers gun comes in two parts, presumably

to aid installation into the cowling, but I assembled this one and painted

it completely before installing it and it fit very well. The very delicate

Lewis gun and its unique Admiralty Top Plane Mounting was puzzled together

from the parts supplied with the kit and from examining available photos.

This was later mounted on the top wing so that it could swivel up and

down: A little finicky, but the final result was worth the effort. The

external elevator bellcranks were added as were the attaching fittings

for the fuselage joint made out of short lengths of Evergreen stock painted

black. Too late I realized there were lifting brackets on the top wing

center section, so I added these with some black decal film cut into tiny

triangles, but they are probably better made with thin card or brass sheet

stock. They still look OK, I think.

The airframe was prepared for rigging by drilling holes with a #80 twist

drill in all the appropriate locations. The top wing was attached by first

fixing the interplane struts to the lower wings with Tamiya Extra Thin

Cement. A simple jig was constructed using foam core illustration board

to which was glued a sheet of graph paper. A few blocks of balsa glued

to this surface helps keep everything  aligned.

When the struts were dry enough the top wing was installed very carefully

again using Tamiya Extra Thin Cement. I went off to watch TV for a while

during which various paint jars and such held everything in proper alignment

until the glue dried. The struts were then fixed in place and reinforced

with a drop of thin superglue. Next the cabane struts were attached. Here

I ran into a little problem as the front cabanes were very slightly short,

and the rear cabanes were too long by about 1mm. I just trimmed them to

fit and all was well. Upon reflection, I believe the interplane struts

are mislabeled in the (Camel F1) instructions. B-19 which are the forward

interplane struts are longer than B-9, the rear struts. I think if one

used the shorter struts forward this would take care of the cabane problem. aligned.

When the struts were dry enough the top wing was installed very carefully

again using Tamiya Extra Thin Cement. I went off to watch TV for a while

during which various paint jars and such held everything in proper alignment

until the glue dried. The struts were then fixed in place and reinforced

with a drop of thin superglue. Next the cabane struts were attached. Here

I ran into a little problem as the front cabanes were very slightly short,

and the rear cabanes were too long by about 1mm. I just trimmed them to

fit and all was well. Upon reflection, I believe the interplane struts

are mislabeled in the (Camel F1) instructions. B-19 which are the forward

interplane struts are longer than B-9, the rear struts. I think if one

used the shorter struts forward this would take care of the cabane problem.

The Camel has double flying wires, which were done with invisible nylon

mending thread fixed with superglue. The remaining rigging and control

cables were done with heat stretched sprue attached with white PVA glue.

The little "Acorn" fitting between the cowl and the top wing

was fabricated from the end of a pointed round toothpick cut and sanded

to shape then reinforced with thin superglue. A small jig helped to attach

the two uppermost wires, which were superglued to the acorn. This assembly

was mounted on the top wing underside. Then it was simply a matter of

attaching the two lower wires with white glue.

All

remaining bits and pieces were installed including the Vickers, propeller,

tailskid, and the wheels, which I gave a slight splay to mimic the sit

of the original, despite the axles not being so. Suddenly, it seemed,

the model was finished! All

remaining bits and pieces were installed including the Vickers, propeller,

tailskid, and the wheels, which I gave a slight splay to mimic the sit

of the original, despite the axles not being so. Suddenly, it seemed,

the model was finished!

Conclusion

Seldom do

I catch myself grinning while building a model, but I did on several occasions

while building this one! Despite the few minor setbacks (most of which

were self-inflicted) and minor shortcomings of the kit, I had a great

time building it. The finished result is a convincing replica of this

pugnacious looking little fighter.

I understand that the kit will be officially released onto the market

sometime this spring, with improvements over this test sample. A Profipack

version will most certainly soon be available, which will include many

of the details in either photoetch or resin that I scratchbuilt into this

one.

Thanks to Eduard for the review

sample, and very special thanks to Matt Bittner for allowing me to build

this kit and for the continued words of encouragement throughout! Thanks

also to the wonderful folks on the WWI Modelers Discussion Forum for their

support and inspiration.

References

Sopwith

2F1 Camel, Windsock Datafile No. 6, J.M. Bruce, Albatros Productions Ltd.,

1987 Sopwith

2F1 Camel, Windsock Datafile No. 6, J.M. Bruce, Albatros Productions Ltd.,

1987

Sopwith Camel, Windsock Datafile No. 26, J.M. Bruce, Albatros Productions

Ltd., 1991

The Camel Fighter, John Pudney, Hamish Hamilton Ltd., 1964

WWI British Aeroplane Colours and Markings, Bruce Robertson, Albatros

Productions Ltd., 1996

Sopwith Fighters in Action, Peter Cooksley, Squadron Signal Publications,

1991

There is also an invaluable collection of Sopwith Camel photos on the

WWI Modelers

Website, many of which are of the 2F1.

|

|